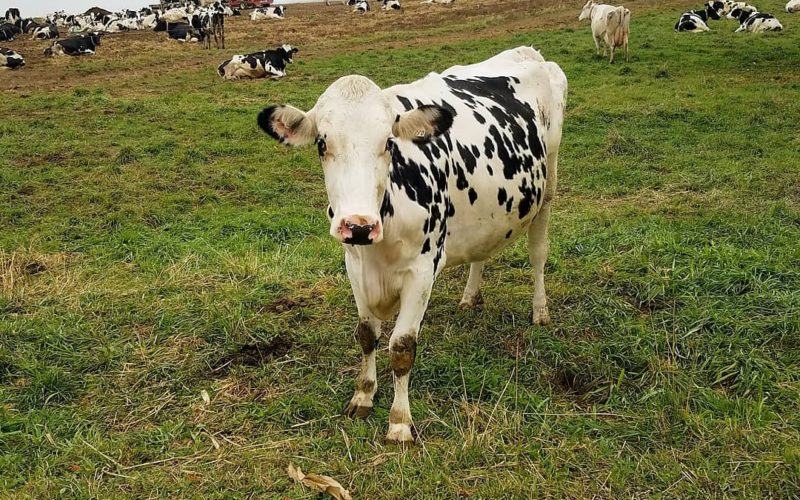

In order to create the most wholesome product within our means, we use only the most wholesome ingredients in our product. And with that comes great risk in regards to texture, consistency, flavor, and shelf life. Our goal has always been to create a product we can feel good about without hiding anything. Transparency was, is, and always will be our MO. As a staff, we care deeply about the food we put into our bodies. And so naturally, we care the same about our customers. We believe in minimally processed ingredients purchased as close to their original condition as possible. The reasons? This gives us more control over the “art” of our craft, and we think it’s better for both you and the world. The downside? Because of this commitment, we often experience hiccups in our production processes. Whether it be a higher butter fat content than usual in our Amish farm sourced, non-homogenized, batch-pasteurized milk and cream, or fresh produce that yielded varied results from the year prior due to a vastly different growing season, the finished sweet treats we offer depend heavily on forces outside our control. We take pride in a somewhat inconsistent product because we believe in authentic flavors and pure ingredients. We are a small-batch, from scratch company. We don’t source our ice cream or gelato base from a factory. We make 99% of our add-ins from scratch right at our little shop – the exceptions of which are sourced from like-minded companies. We utilize Michigan-based growers as much as possible and we seek out organic ingredients from the USA and all over the world from carefully selected suppliers who operate model businesses for sustainability and ethics such as Mountain Rose Herbs and Tierra Farms. Have you ever tried our Vegan Lavender Blueberry and seen a difference in color from one visit to the next? Our blueberries are all Michigan sourced. Supplies and varieties may vary, and growing conditions change every year. These factors can contribute to differences in color and flavor potencies. The same goes for all produce used in our ice creams and vegan gelatos (gelati). Our Mexican Chili Hot Chocolate can be a spicy kick in the mouth or a pleasant warmth on the tongue. The grass-fed cows that produce our milk and cream for the base of our ice cream are not factory farmed but instead graze comfortably on Amish farms 6 hours from Grand Rapids. Because of this highly nutrient-rich diet, the resulting product has a grassier, almost hay-like flavor in spring once the cows have more of a chance to graze on fresh pasture. The milk and cream mixture can also vary in butter fat percentage due to the small batch nature of the cream separation. Sourcing the dairy is a cooperative effort among a handful of Amish farmers in the Kalona, IA area. All the dairy we use is batch pasteurized in order to retain as many nutrients as possible. And the term non-homogenization refers to the minimal processing of our dairy. Both of these processes lead to decreased shelf life (more processing = longer shelf life = more difficult to digest). We use minimal stabilization techniques to increase the longevity of our ice cream and gelato (flavor and texture), but we refuse to use the highly processed chemically-derived stabilizers found in many commercially available mass-produced brands. If we wanted a completely uniform, never-varies-from-the-norm product, we’d buy dairy from factory farms and purchase fruit from industrial processors who aggregate harvests from all over, standardizing every batch. But we care about the well-being of the animals we source from. We care about the high nutrient-density of our produce. And, ultimately, we care about how our product affects the health of our customers. As a result, our product has inconsistencies and changes from one batch to the next. Of course we still strive to be as consistent as possible given the unpredictability of our ingredients. But we care more about transparency and putting good, wholesome ingredients into our sweets. We will always care more about maintaining excellency through our patchwork sourcing model than buying cheap, hyper-processed ingredients to lower costs and increase consistency. We continually grow as we adapt our processes to accommodate our ever-changing ingredients. And we continue to hone our production efforts as we understand more fully the nuances and fluctuations of each individual ingredient. We are always happy to answer questions and receive feedback on anything and everything we serve. Wholesome, handcrafted, and from scratch come with their fair share of hurdles to leap over. And we meet those challenges with open arms. Because in the end, why try if we are not trying our best?

-Love’s Production Crew